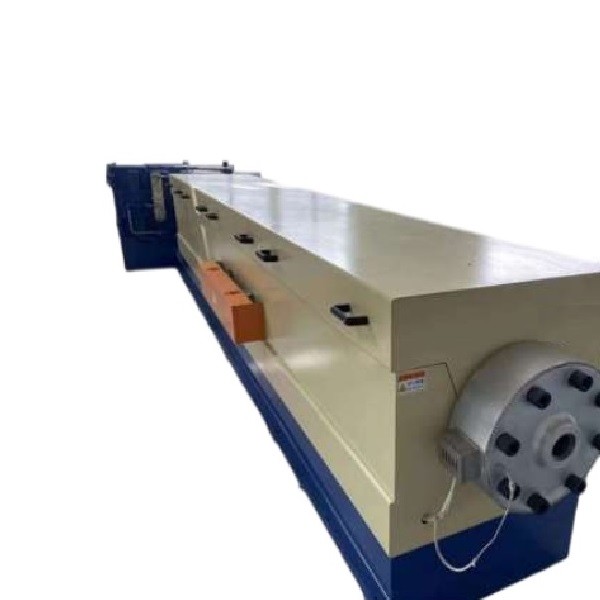

Description

DW series single screw extruders with special structure are widely used for PP, PET non-woven fabric extrusion and melt spinning of PET, PA6, PA66, PP chips. We also supply DW90/18, DW105/13, DW105/18, DW120/18 extruders for recycled materials.

Main characteristics:

1) Optimized design, high quality material for screw barrel. Lower wear out, good self lubrication.

2) Special protective cover saves energy and easy disassembly.

3) High precision gearbox with carbonized, hardened and polished gears. Lower noise, long span-life .Safety in lower speed.

Parameters for chemical fiber extruder:

|

Model |

Screw Dia.(mm) |

L/D Ratio |

Speed of screw (RPM) |

Motor Power(kw) |

Heating Power(kw) |

Heating Zones |

Capacity (kg/h) |

|

DWH45 |

45 |

25:1 |

20-90 |

7.5 |

8 |

3 |

35 |

|

DWH65 |

65 |

25:1 |

20-90 |

18.5 |

16 |

5 |

75 |

|

DWH80 |

80 |

25:1 |

20-80 |

37 |

27 |

5 |

110 |

|

DWH90 |

90 |

25:1 |

20-70 |

45 |

32 |

5 |

190 |

|

DWH105 |

105 |

25:1 |

20-60 |

55 |

45 |

5 |

290 |

|

DWH120 |

120 |

25:1 |

20-60 |

75 |

54 |

6 |

390 |

|

DWH135 |

135 |

25:1 |

20-60 |

90 |

63 |

6 |

550 |

|

DWH150 |

150 |

25:1 |

20-60 |

110 |

76.5 |

6 |

650 |

|

DWH160 |

160 |

25:1 |

20-60 |

132 |

85.5 |

6 |

700 |

|

DWH170 |

170 |

25:1 |

20-60 |

160 |

103.5 |

6 |

850 |

|

DWH180 |

180 |

25:1 |

20-50 |

160 |

110 |

7 |

950 |

|

DWH200 |

200 |

25:1 |

20-50 |

200 |

150 |

7 |

1050 |

Parameters for non-woven fabrics extruder:

|

Model |

Screw Dia.(mm) |

L/D Ratio |

Speed of screw (RPM) |

Motor Power(kw) |

Heating Power(kw) |

Heating Zones |

Capacity (kg/h) |

|

DWW105 |

105 |

30:1 |

75 |

55 |

40 |

5 |

160 |

|

DWW120 |

120 |

30:1 |

75 |

75 |

42 |

6 |

200 |

|

DWW130 |

130 |

30:1 |

75 |

90 |

42 |

6 |

240 |

|

DWW135 |

135 |

30:1 |

75 |

90 |

54 |

6 |

260 |

|

DWW150 |

150 |

30:1 |

75 |

110 |

72 |

6 |

320 |

|

DWW160 |

160 |

30:1 |

75 |

132 |

72 |

6 |

400 |

|

DWW170 |

170 |

30:1 |

75 |

160 |

84 |

6 |

450 |

|

DWW180 |

180 |

30:1 |

75 |

185 |

96 |

7 |

520 |

|

DWW200 |

200 |

30:1 |

75 |

220 |

130 |

7 |

750 |

|

DWW220 |

220 |

33:1 |

75 |

280 |

160 |

8 |

1000 |