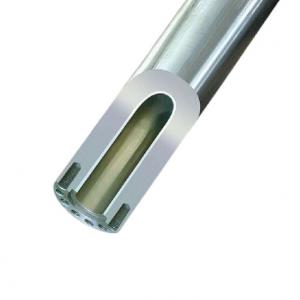

Description

| Specification: ∅15-300mm | |

| L/D Ratio: 10-55 | |

| According to different products and formulations to design screw structure and compression ratio. | |

| Steel Material | Heat Treatment |

| High Quality Alloy Steel | |

| 1)38CrMoAlA(SACM645) |

Nitriding Treatment or Bimetallic Treatment(Spray alloy power on the screw's flights) or WC-Co coated on the surface of screw |

| 2)42CrMo(SCM440) | Hardchrome Plating |

| 3)SKD61 | Vacuum Quenching |

| 4)9Cr18MoV | High Frequency Quenching |

| 5)GH113 | Natural Harden after High Temperature |

| Technical Parameters | |

| Tempering Hardness: HB280-HB300 | Chrome Plating Thickness: 0.025-0.1mm |

| Nitriding Hardness: HV900-HV1100 | Chrome Plating Hardness: ≧HV900 |

| Nitriding Thickness: 0.5-0.8mm | Bimetallic Alloy Depth: 1.5-2mm |

| Nitriding Brittleness: 1 Level | Bimetallic Alloy Hardness: HRC58-HRC65 |

| Surface Roughness: ≦Ra0.4 | |

| Screw Straightness: 0.015mm | |